One of the key factors that determine the quality of printing is the adhesion of the ink to the substrate. However, due to the difference in interfacial tension between the ink and the substrate material, it is often difficult for the ink to adhere evenly, affecting the final printing effect. In response to this problem, plasma technology can be used to pretreat the surface of the material, effectively introduce polar functional groups, significantly improve surface energy and wettability, thereby enhancing ink adhesion, ensuring clear and firm graphics, and comprehensively improving printing quality and durability.

Plasma surface treatment, which provides stronger adhesion and higher yield of finished products for screen printing, is one of the key technologies to enhance the competitiveness of the process.

Flexibility : Plasma technology has strong adaptability and can efficiently process various complex materials and structural surfaces, providing strong support for diversified screen printing processes.

High efficiency : Plasma treatment has the surface modification ability of high efficiency, low energy consumption and non-destructive materials. It not only improves the quality and consistency of screen printing, but also gives a variety of functions to help expand the application of intelligent manufacturing and precision printing.

Polymer materials

Polymer materials Due to the low surface energy of polymer materials, it is often difficult for ink to attach, which affects the printing quality. Through plasma treatment, nano-scale rough structures can be formed on the surface of the material, and polar functional groups are introduced to significantly improve the adhesion and hydrophilicity, thereby significantly enhancing the wettability and adhesion of the ink, and providing stable and reliable surface conditions for subsequent printing.

Metal

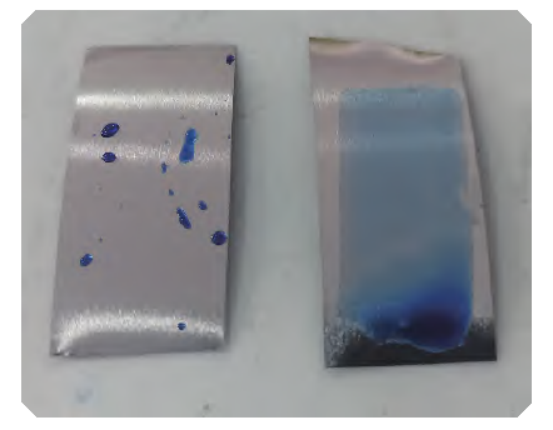

Metal The metal surface usually has a high surface energy, which is conducive to ink adhesion. However, materials such as aluminum will form a dense oxide film after oxidation, resulting in a decrease in surface energy and affecting printing quality. Taking stainless steel signs and decorative parts as an example, the untreated surface energy is only about 30 dynes / cm. After low temperature plasma treatment, it can be increased to 72 dynes / cm, which significantly enhances ink adhesion and weather resistance ( see Fig.1 ).

Fig.1 Comparison of metal materials before and after plasma treatment

Glass

Glass The surface of the glass is smooth and easy to adsorb organic pollutants in the production process, and the adaptability of the surface to the subsequent process is further reduced after the functional layer is coated. Plasma treatment can construct nano-scale micro-roughness structure on the surface of glass, which can effectively improve the surface roughness without affecting its optical transmittance and refractive characteristics. The introduction of active ions can also enhance the surface energy and significantly improve the adhesion and printability of the ink.

HOT PRODUCTS

Plasma

Copyright@ NAEN Technology Co., Ltd. All Rights Reserved.|

Sitemap

| Powered by