DESCRIPTION

Vacuum plasma cleaning equipment is composed of electrical control and operating system, vacuum chamber, gas supply system, 13.56MHz RF power supply, vacuum spring and other parts. use etc.

The active physical and chemical electromagnetic fluid characteristics of ions can realize a series of reaction processes and treatment effects that cannot be achieved by traditional wet treatment, and have the advantages of high production speed

Fast, high energy, no pollution, wide range of processing objects, low overall cost, no need for drying treatment, small footprint and so on.

Product features of vacuum plasma cleaning equipment:

* The power of the RF power supply is adjustable from 0 to 600W, and the frequency is 13.56MHz. At the same time, the power supply matching system is used to adjust the load impedance to ensure the best iso

Ion density and repeatability.

*The main body of the electrode plate is made of stainless steel, which can be connected to the positive or negative pole of the power supply through the electrode connector. The electrode plate is fixed in the vacuum chamber by insulating blocks on both sides.

In the whole electrode system, the polarity and spacing of the electrode plates can be selected according to different requirements to obtain the most suitable plasma.

*The gas supply system uses a high-precision flowmeter to precisely adjust the flow of working gas, and uses a high-stability vacuum spring to achieve a balanced discharge of exhaust gas.

* High reliability and stability, efficient power output, compact structure design, small size, light weight, perfect protection function and so on.

*The front door is opened, the rear is opened with exhaust holes and power cord holes, and the side is opened with air intake holes, so as to form a dynamic cycle and even air intake to improve the cleaning effect

*Two independent gas circuit controls are convenient for exploring the influence of different gas ratios on the cleaning effect.

*The material of the vacuum chamber is 316 stainless steel as the discharge chamber, which has good corrosion resistance, strong heat resistance, good strength at low temperature, and is suitable for hot processing such as stamping and bending.

Good sex, non-magnetic.

Application fields of vacuum plasma cleaning equipment:

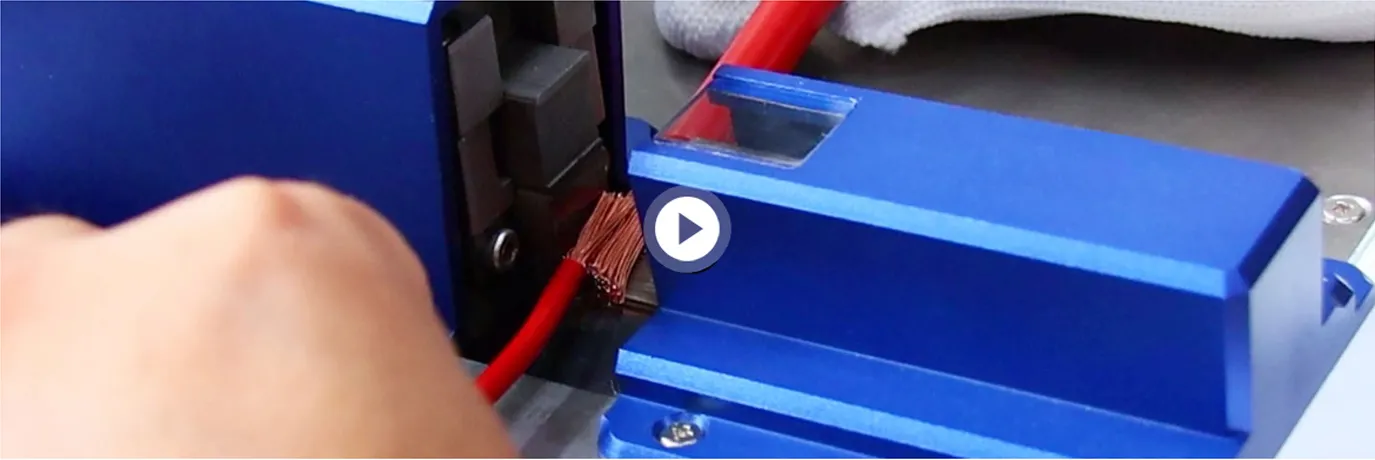

Wire bonding pretreatment

Integrated circuit bonding requires that the bonding area must be free of dust, oil and other pollutants, and has good wetting properties. After cleaning by vacuum plasma cleaning equipment, it can effectively remove

The surface of the bonding area is dirty and activated, which increases the pull force of the wire bond and improves the reliability and yield of the packaged device.

Pretreatment for Die Attach

The chip and the packaging substrate are two materials with different properties. If the surface adhesion of the two materials is poor, gaps will appear during the bonding process. After the chip is packaged,

It is prone to problems such as falling off. By plasma cleaning the chip and the substrate, the fluidity of the bonding epoxy resin on the surface can be greatly improved, and the chip can be reduced.

The delamination with the substrate increases the stability and service life of the product.

Lead frame surface treatment

In the field of microelectronic packaging, plastic packaging of copper alloy material lead frames is usually used. Copper oxides and some organic pollutants will affect the quality of bonding and bonding.

After cleaning by vacuum plasma cleaning equipment, the surface activation effect of the lead frame can be improved, and the yield rate of the finished product will be greatly improved. Compared with traditional chemical liquid cleaning

In other words, more green and environmentally friendly.

Other

Surface activation modification of ceramics, glass, rubber, and plastic polymer materials to improve surface wettability and adhesive properties

COB, COG, COF, ACF process wire bonding, pre-welding treatment

CCM camera module, LCD display module cleaning

Vacuum plasma cleaning equipment reacts with the pollutant molecules contained in the plasma or uses the generated particles to bombard the surface to be cleaned, so that the pollutants are removed from the surface.

The cleaning method of washing surface separation, it should be pointed out that chemical reaction or physical bombardment will also modify the cleaned surface to improve wettability and membrane adhesion force.

PRODUCT FEATURES

Fast Deposition Rate

Good Film Quality

Process Stability

High Productivity

Fully Automatic

Simple Operation

Plasma

Copyright@ NAEN Technology Co., Ltd. All Rights Reserved.|

Sitemap

| Powered by